As public awareness of environmental and occupational health grows, so does the demand for cleaner, safer air. Dust sensors—designed to monitor the concentration of airborne particulate matter—play a pivotal role in maintaining healthy living and working environments. These devices are now widely deployed in urban planning, industrial safety, and environmental protection. In particular, construction sites—often major contributors to urban dust pollution—benefit greatly from real-time dust monitoring solutions. When dust levels surpass safe thresholds, appropriate control measures can be implemented, minimizing both environmental impact and health hazards.

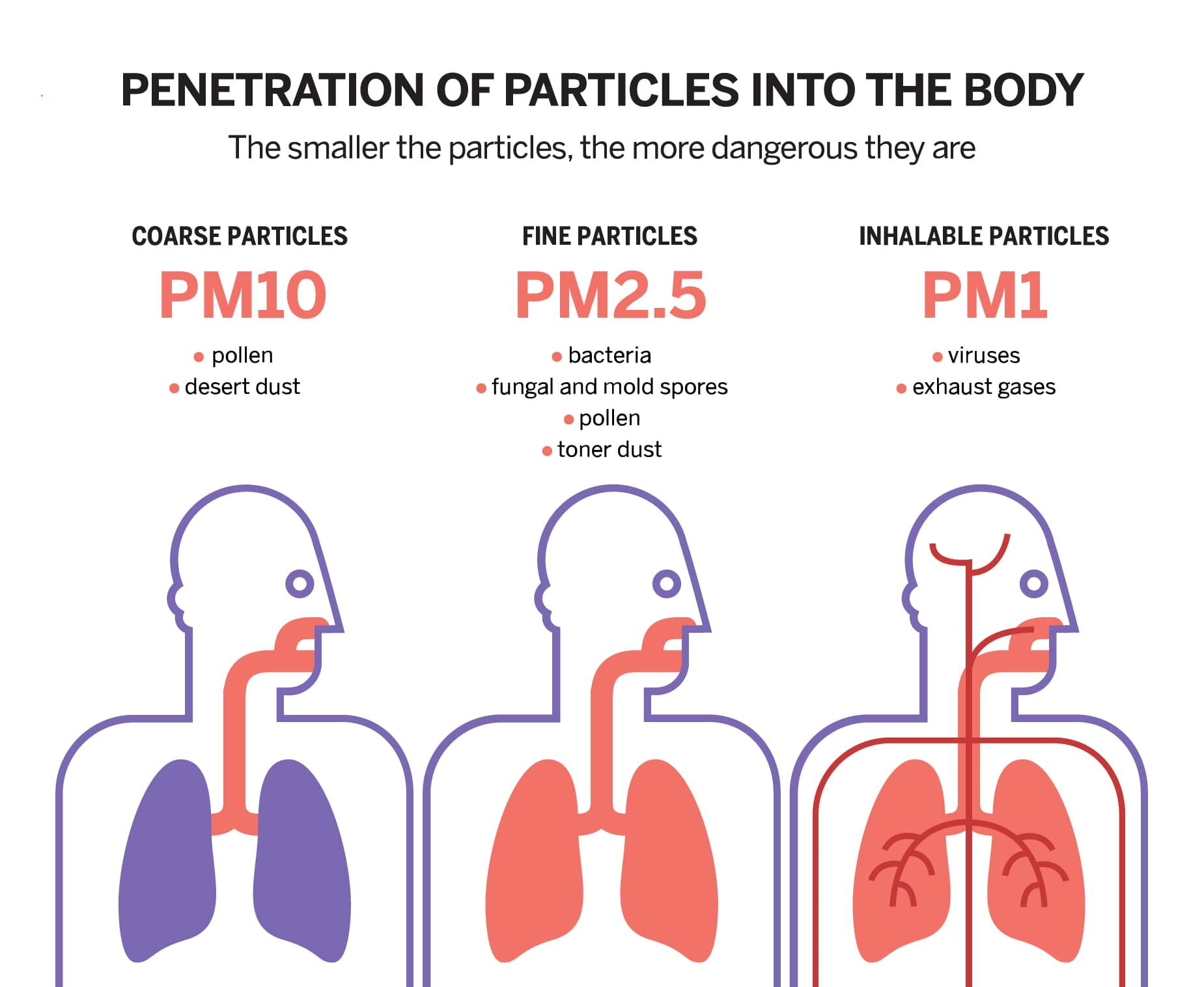

Particulate matter (PM), especially PM2.5 and PM10, poses significant risks to respiratory health. Generated from industrial operations, construction activity, traffic emissions, and other urban sources, fine dust particles can infiltrate deep into the lungs, leading to asthma, bronchitis, and even cardiovascular diseases. Construction sites are among the most substantial sources of airborne dust due to excavation, demolition, material handling, and vehicular movement. Without proper monitoring and control, these particles become airborne and contribute to city-wide pollution.

Installing dust monitoring systems at such sites not only enhances compliance with environmental regulations but also helps in protecting workers and surrounding communities. Early detection allows for prompt deployment of dust suppression methods such as water spraying, dust screens, and ventilation systems.

Modern dust sensors operate using several principles to detect and quantify airborne particles. The most common technologies include:

Optical Scattering: Dust particles scatter light as they pass through a laser beam or LED. The intensity and angle of scattered light provide information on particle size and concentration.

Laser-based Optical Scattering: A more advanced form of the above, this method offers greater accuracy, repeatability, and sensitivity. It is now widely adopted in Europe, the United States, and Japan, replacing older optical technologies.

Beta-ray Radiation: This technique uses beta radiation to measure particulate mass on a filter tape. It is highly accurate but more expensive and often reserved for regulatory-grade monitoring.

Microbalance Weighing: This ultra-precise method uses a sensitive balance to weigh collected particles. However, it is costly and typically dominated by a few U.S.-based manufacturers.

Electrostatic Induction: Dust particles are charged and then measured as they pass through an electric field. Commonly used in leak detection in dust collection systems.

Piezoelectric Balance: Particles are measured via vibration-based detection. Though accurate, this method is complex and not widely produced.

Each technique comes with trade-offs between cost, precision, complexity, and application suitability.

Modern industrial dust sensors, especially those used in outdoor environments, are designed with several advanced features to meet demanding applications:

High Data Accuracy: Laser-based detection ensures high-precision measurement of particles as small as 0.3μm with sensitivity levels down to 0.001 mg/m³.

Multi-Parameter Capability: Capable of simultaneously monitoring PM2.5, PM10, and Total Suspended Particles (TSP).

Adaptability: Sensors adjust to different ambient conditions, including humidity, temperature, and various dust types, ensuring stable operation in diverse environments.

Flexible Data Output: Interfaces include RS485 (Modbus protocol), RS232, and UART, allowing integration into broader environmental monitoring systems or automated dust suppression mechanisms.

Alarm Integration: Sensor systems can be connected to audio-visual alarms to provide real-time alerts when dust levels exceed preset limits.

Intelligent Monitoring: Real-time analysis and system diagnostics offer immediate feedback on sensor performance and environmental changes.

Dust concentration sensors have become indispensable in various sectors, serving multiple purposes ranging from public health protection to scientific research. Key application areas include:

Dust sensors are deployed to monitor particle emissions in factories, mining areas, and processing facilities. This not only helps in maintaining regulatory compliance but also ensures occupational safety.

Hygiene and epidemic prevention stations use these sensors to measure inhalable particles in public spaces, reducing the spread of dust-related illnesses.

Environmental agencies utilize dust sensors to track pollution levels, identify sources, and evaluate the effectiveness of mitigation efforts.

In city environments, dust sensors help control indoor and outdoor air quality, contributing to clean air initiatives and smoking bans.

From filter material testing to atmospheric pollution modeling, dust sensors are critical in providing reliable data for academic and field studies.

Sensors are mounted at construction zones to monitor real-time dust levels and trigger mitigation measures when necessary, minimizing pollution spread.

Facilities involved in the production of precision instruments, semiconductors, pharmaceuticals, and food products require dust-free environments. Dust sensors are essential for air quality management in these industries.

Monitoring dust exposure in workplaces helps enforce safety regulations and protects employees from long-term respiratory risks.

Institutions involved in meteorology and atmospheric science rely on dust concentration data for forecasting and environmental modeling.

Dust sensors are also used in smart building systems to ensure healthy indoor environments in offices, homes, and commercial spaces.

With the global push toward smart city development, dust sensors have found new relevance in networked environmental monitoring systems. Compared to traditional atmospheric monitoring stations, which are expensive and difficult to deploy at scale, compact air quality micro-stations equipped with dust sensors offer an affordable, flexible, and efficient alternative.

These small-scale stations are widely adopted by local governments for neighborhood-level air monitoring, traffic pollution analysis, and school zone air quality assessments. Their modular design allows for easy installation on street lights, rooftops, or utility poles. Data from these systems can be transmitted in real-time to centralized platforms for analysis and visualization, enabling informed urban planning and quicker response to air quality issues.

Despite their small size and low deployment cost, the accuracy and reliability of dust monitoring systems largely depend on the quality of the core component—the dust sensor itself. High-grade sensors ensure data consistency, minimize false alarms, and provide long-term operational stability, which is vital for decision-making at both local and national levels.

Poor-quality sensors, on the other hand, can lead to erroneous readings, misinformed policy decisions, and ultimately, ineffective pollution control. Therefore, investing in sensors from reputable manufacturers with proven calibration standards and robust construction is essential.

As urban development accelerates and environmental standards tighten, dust concentration sensors have become critical tools for air quality management. Their ability to provide real-time, precise data on particulate matter allows for rapid intervention and long-term planning to mitigate the health and environmental impacts of dust pollution.

From construction sites and industrial zones to research labs and public health agencies, these sensors empower users to monitor, manage, and improve air quality efficiently. In smart cities and traditional settings alike, dust sensors will continue to play a central role in safeguarding public health and supporting environmental sustainability. Their growing adoption marks a significant step toward cleaner, healthier, and more informed communities.

Previous: How Total Volatile Organic Compounds (TVOCs) Affect Air Quality

Next: The Role of Laser Dust Sensors in Industrial and Environmental Safety